In-line blending

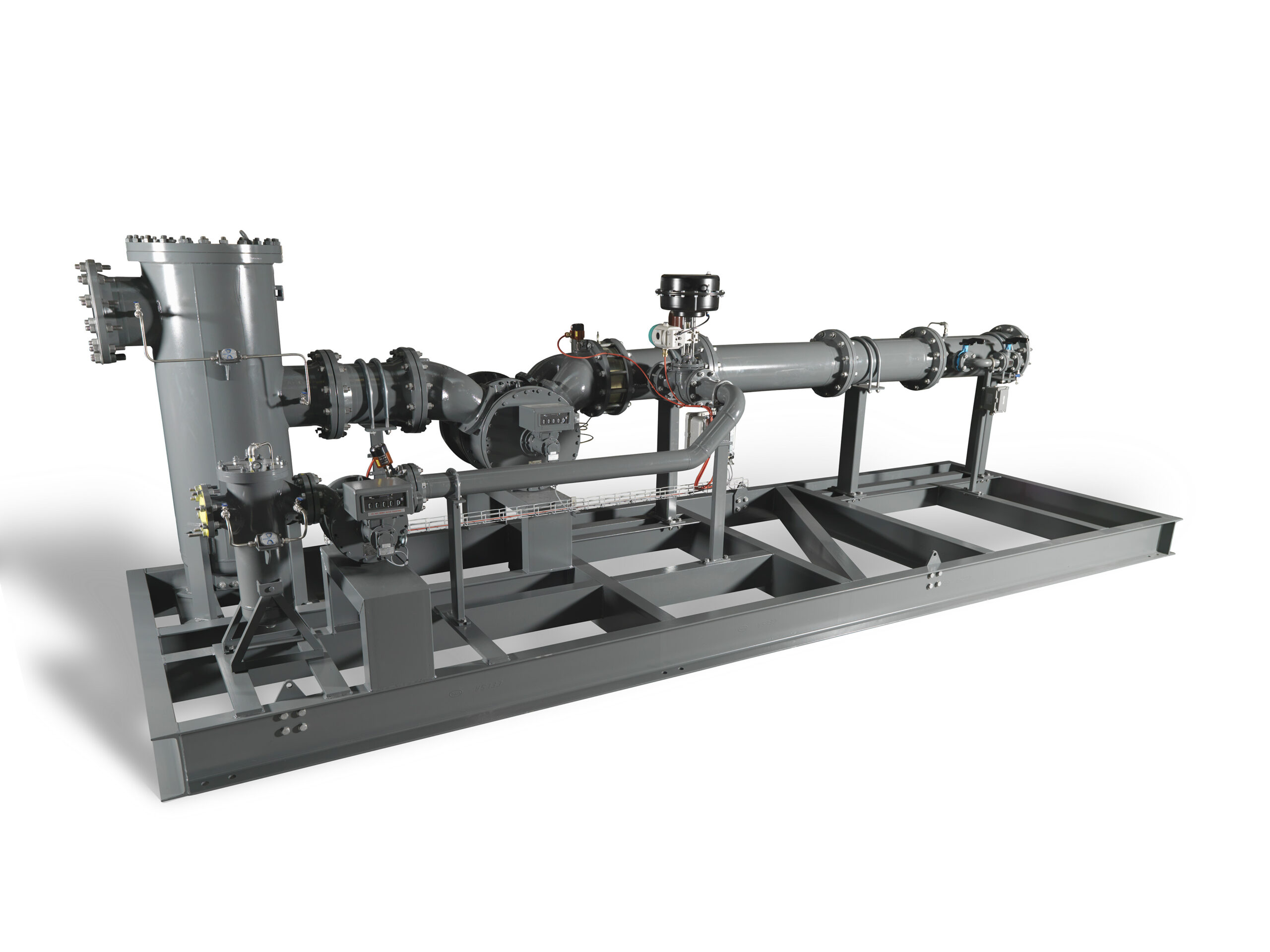

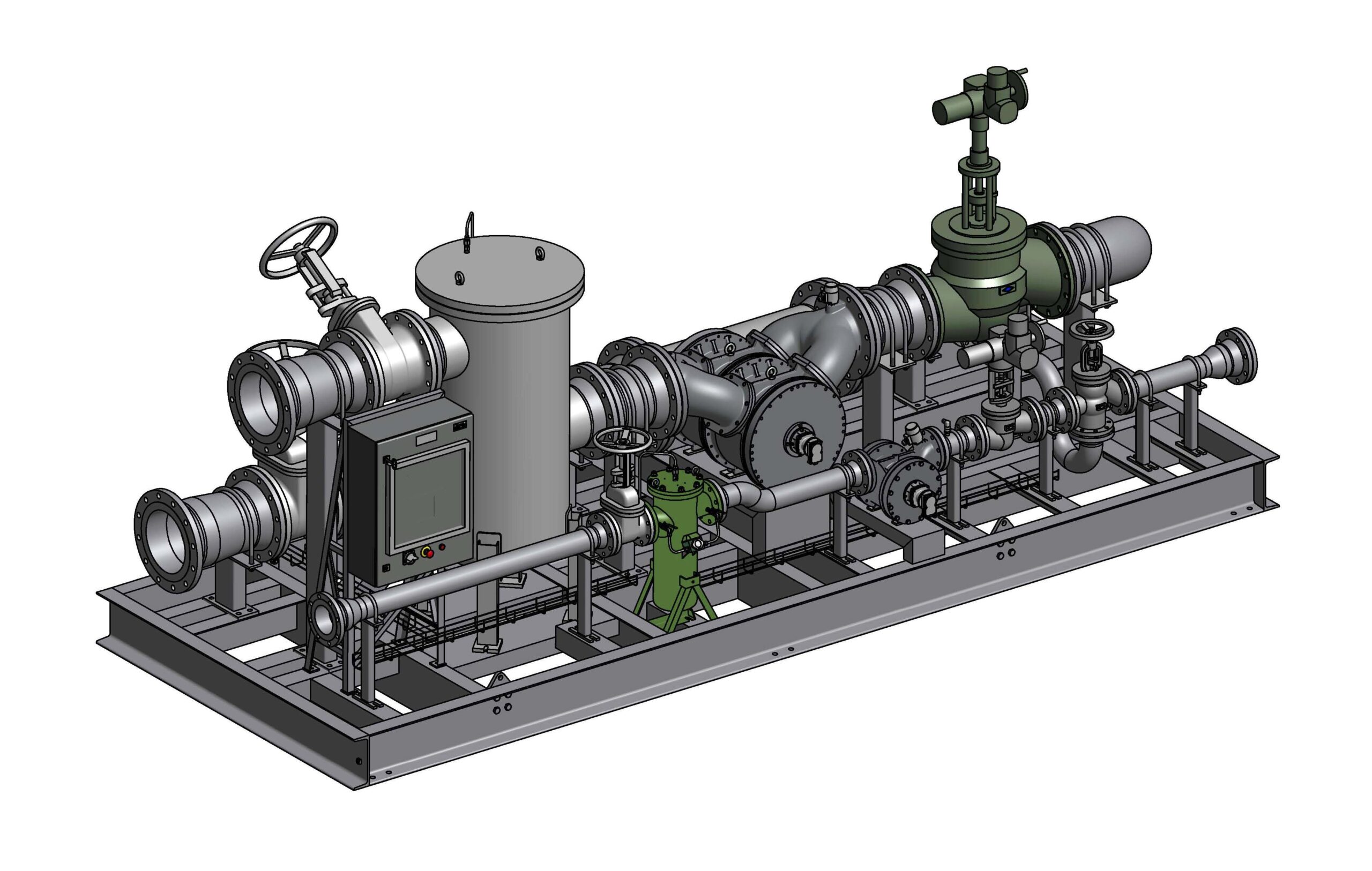

Oil Batching and Blending Systems

VAF Instruments designs, builds and manufactures in-line blending systems capable of producing specifically defined grades of oil in any quantity, ensuring the highest levels of speed and accuracy.

Interested in this product? Contact us

We present: Oil Batching and Blending Systems

With VAF Instruments, you have the option to choose from a range of components that, when combined, result in the most advanced liquid measuring and control systems. Accessories such as flow computers, batch controllers, ratio controllers, along with electric or pneumatic knock-off and control valves, from the foundation of a fully assembled system. Additionally, VAF provides worldwide service support, enabling the installation and commissioning of your new system on-site.

To continuously meet the evolving needs of our customers, VAF Instruments stays abreast of new technologies and strives to stay ahead of market developments. This ongoing commitment represents the enduring challenge embraced by VAF.

How to create your own personal system

Prior to initiating the development of a tailor-made system, we conduct a comprehensive investigation of your preferences. The detailed proposal for a complete system is not only shaped by VAF’s expertise but is predominantly influenced by your specific knowledge of the application. Ultimately, this approach results in systems that meet your requirements and are constructed according to your envision specifications.

User benefits

- Single point of contact for products, engineering, service and parts

- In-depth knowledge of the products and optimal combinations between them

- ISO 9001 certified quality assurance system

- Service facilities in over 40 countries, strategically located in major ports, industrial and shipbuilding areas worldwide

- Guaranteed reliability

A few examples of VAF Instruments custom-made solutions

- Viscosity control of intermediate and heavy fuel oils used for main and auxiliary diesel engines

- Application of emulsion adhesives to audio and video tapes or photographic materials

- Precision filling of hydraulic shock absorbers

- Addition of glue and pigment in the packaging industry

- Coloring of fuel oils, textiles, paper, leather and plastics

- Injection of oils, fats, and flavorings in the food industry

- Comprehensive blending installations for fuel and lubricating oils

- Overload protection of machinery in paper mills and steel industry

- Detection of misfiring in large engines on board ships

Advanced liquid measuring