Torque and speed measurements

T-Sense®

The utilization of a T-Sense® torque measuring system translates to efficiency improvement, overload protection and the prevention of breakdown costs. In the shipping industry, its application has, in some instances, resulted in fuel savings of up to 5%. The T-Sense® measuring system, based on optical displacement technology, can be easily mounted around propeller or drive shafts.

Interested in this product? Contact us

We present: T-Sense®

The T-Sense® is an intelligently designed optical torque measuring system that can be easily mounted around the shaft by the vessel’s crew or shipyard without the need for engineering or commissioning assistance.

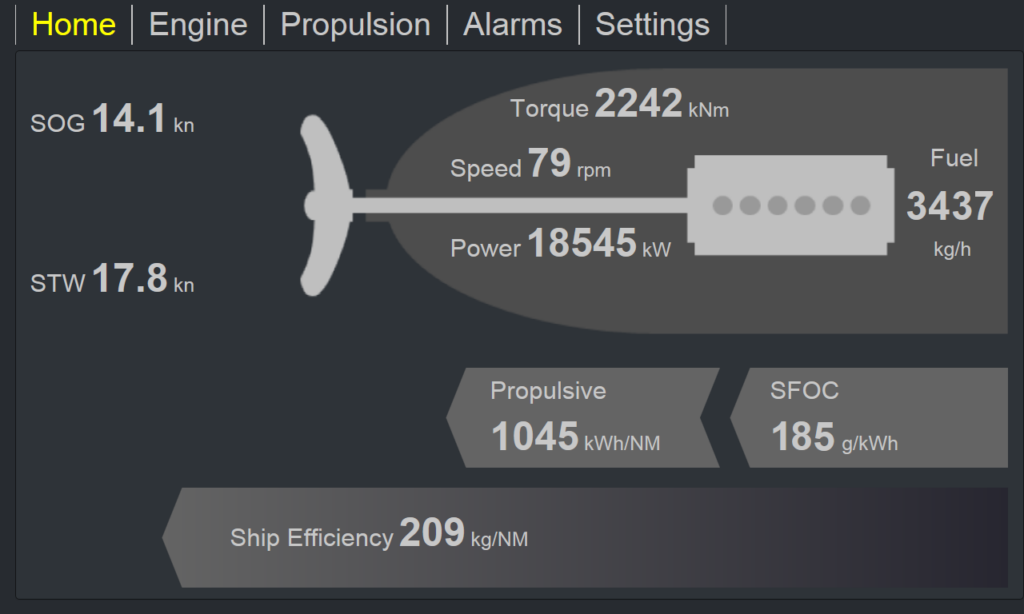

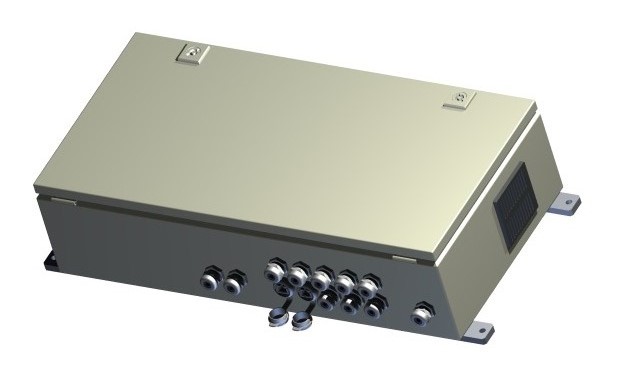

With the PEM4 Propulsion Efficiency Monitor, VAF Instruments introduces a cutting-edge monitoring system that leverages years of experience and proven technology, enhanced by modern user-friendly electronic. The PEM4 system is capable of monitoring one or two T-Sense® torque measuring systems alongside the fuel consumption of up to six engines/consumers (max. 12 VAF flowmeters).

The PEM4 Propulsion Efficiency Monitor stands out for its user-friendly menu structure, providing easy access to all measured and calculated data. These data are presented on the screen in both numerical en graphical formats. The PEM4 system empowers ship owners to enhance vessel efficiency and conveniently monitor engine performance.

Features

The standard T-Sense® system, rooted in torque and speed measurements, facilitates the calculation of power on the shaft. The system can be expanded with various modules, including:

- Energy consumption

- Actual fuel consumption per engine, per genset or boiler

- Specific fuel consumption per Kw (SFOC of main engines)

- Fuel consumption per nautical mile

- Total power calculation

- Propeller thrust measurement

For the extensions, additional signals, such as fuel flows, fuel temperature, speed log, GPS, or shaft generator power level, can be integrated into the PEM4 system. Combined with the standard torque, speed, and power signals, the PEM4 system adeptly calculates the desired data.

Applications

The standard design of the PEM4 Propulsion Efficiency Monitor is versatile and suitable for various applications, including:

- Continuous power output measurements for ship propulsion

- Continuous power and fuel consumption management

- Direct visual control of changes in engine setting, trim and draught

- Continuous monitoring of torque, speed, power, or thrust

User benefits

- Fuel savings through ship efficiency improvement:

- Prevention of damage and overhaul costs

- Installation without the need for engineering and commissioning assistance

- Single communication cable to the bridge

- Streamlined installation without the time-consuming mounting of strain gauges

- Competitive pricing and efficient delivery times

- Robust design, maintenance-free, with no wear and tear

- Worldwide service network of certified VAF agents

efficiency improvement